CEM 1 CEM 3 PCB 8 Layer Printed Circuit Board Assembly , EMS PCBA

Quick Detail:

- UL,ROHS,SGS,ISO

- Layer: 1-30 layer

- Material:CEM-1, CEM-3 FR-4, FR-4 High TG, Polyimide, Aluminum-based material.

- min.line width:0.075mm(3mil)

- min.line spacing:0.075mm(3mil)

- Surface finish:HAL, HAL Lead free,Immersion Gold/ Silver/Tin,Hard Gold, OSP

- PCB/PCB Assembly manufacturing :OEM/ODM service

Detailed Specification of PCB Manufacturing

|

1

|

layer

|

1-30 layer

|

|

2

|

Material

|

CEM-1, CEM-3 FR-4, FR-4 High TG,

Polyimide,

Aluminum-based

material.

|

|

3

|

Board thickness

|

0.2mm-6mm

|

|

4

|

Max.finished board size

|

800*508mm

|

|

5

|

Min.drilled hole size

|

0.25mm

|

|

6

|

min.line width

|

0.075mm(3mil)

|

|

7

|

min.line spacing

|

0.075mm(3mil)

|

|

8

|

Surface finish

|

HAL, HAL Lead free,Immersion Gold/

Silver/Tin,

Hard Gold, OSP

|

|

9

|

Copper thickness

|

0.5-4.0oz

|

|

10

|

Solder mask color

|

green/black/white/red/blue/yellow

|

|

11

|

Inner packing

|

Vacuum packing,Plastic bag

|

|

12

|

Outer packing

|

standard carton packing

|

|

13

|

Hole tolerance

|

PTH:±0.076,NTPH:±0.05

|

|

14

|

Certificate

|

UL,ISO9001,ISO14001,ROHS,TS16949

|

|

15

|

Profiling punching

|

Routing,V-CUT,Beveling

|

Detailed Specification of Pcb Assembly

|

1

|

Type of Assembly

|

SMT and Thru-hole

|

|

2

|

Solder Type

|

Water Soluble Solder Paste,Leaded and Lead-Free

|

|

3

|

Components

|

Passives Down to 0201 Size

|

|

BGA and VFBGA

|

|

Leadless Chip Carries/CSP

|

|

Double-Sided SMT Assembly

|

|

Fine Pitch to 08 Mils

|

|

BGA Repair and Reball

|

|

Part Removal and Replacement-Same Day Service

|

|

3

|

Bare Board Size

|

Smallest:0.25x0.25 Inches

|

|

Largest:20x20 Inches

|

|

4

|

File Formats

|

Bill of Materials

|

|

Gerber Files

|

|

Pick-N-Place File(XYRS)

|

|

5

|

Type of Service

|

Turn-Key,Partial Turn-Key or Consignment

|

|

6

|

Component Packaging

|

Cut Tape

|

|

Tube

|

|

Reels

|

|

Loose Parts

|

|

7

|

Turn Time

|

15 to 20 days

|

|

8

|

Testing

|

AOI inspection

|

|

X-Ray inspection

|

|

In-Circuit testing

|

|

Functional test

|

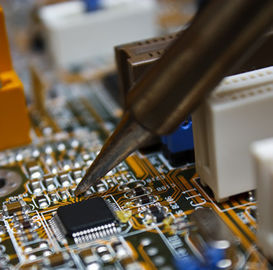

Welcome to Huaswin!

Huaswin Electronics is a professional PCB & PCB Assembly manufacturer, located in Shenzhen, China.

We supply one-stop facility services: PCB design, PCB fabrication, components procurement, SMT and DIP

assembly ,IC pre-programming / burning on-line, testing, packing.

PCB capability and services:

1. Single-sided, double-sided & multi-layer PCB (up to 30 layers)

2. Flexible PCB (up to 10 layers)

3. Rigid-flex PCB (up to 8 layers)

4. CEM-1, CEM-3 FR-4, FR-4 High TG, Polyimide, Aluminum-based material.

5. HAL, HAL lead free, Immersion Gold/ Silver/Tin, Hard Gold, OSP surface treatment.

6. Printed Circuit Boards are 94V0 compliant, and adhere to IPC610 Class 2 international PCB standard.

7. Quantities range from prototype to volume production.

8. 100% E-Test

PCB Assembly services:

SMT Assembly

Automatic Pick & Place

Component Placement as Small as 0201

Fine Pitch QEP - BGA

Automatic Optical Inspection

Through-hole Assembly

Wave Soldering

Hand Assembly and Soldering

Material Sourcing

IC pre-programming / Burning on-line

Function testing as requested

Aging test for LED and Power boards

Complete unit assembly (which including plastics, metal box, Coil, cable assembly etc)

Packing design

Conformal coating

Both dip-coating and vertical spray coating is available. Protecting non-conductive dielectric layer that is

applied onto the printed circuit board assembly to protect the electronic assembly from damage due to

contamination, salt spray, moisture, fungus, dust and corrosion caused by harsh or extreme environments.

When coated, it is clearly visible as a clear and shiny material.

Complete box build

Complete 'Box Build' solutions including materials management of all components, electromechanical parts,

plastics, casings and print & packaging material

Testing Methods

AOI Testing

·Checks for solder paste

·Checks for components down to 0201"

·Checks for missing components, offset, incorrect parts, polarity

X-Ray Inspection

X-Ray provides high-resolution inspection of:

·BGAs

·Bare boards

In-Circuit Testing

In-Circuit Testing is commonly used in conjunction with AOI minimizing functional defects caused by

component problems.

· Power-up Test

· Advanced Function Test

· Flash Device Programming

· Functional testing

ISO Certification:

Huaswin’s production facility is ISO9001 certified to ensure top quality production of your product!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!