Introduction

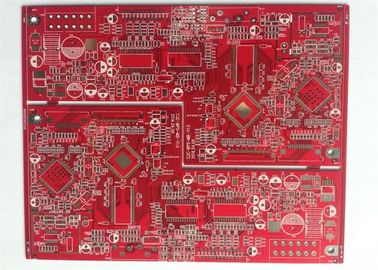

Multilayer printed circuit boards (PCBs) represented the next major evolution in fabrication technology. From the base platform of double sided plated thru came a very sophisticated and complex methodology that would again allow circuit board designers a dynamic range of interconnects and applications.

Multilayer circuit boards were essential in the advancement of modern computing. The multilayer PCB basic construction and fabrication are similar to micro chip fabrication on a macro size. The range of material combinations is extensive from basic epoxy glass to exotic ceramic fills. Multilayer can be built on ceramic, copper, and aluminum. Blind and buried vias are commonly produced, along with pad on via technology.

Production Process

1. Chemical Clean

In order to obtain good quality etched pattern, it is necessary to ensure a strong bond of the resist layer and the substrate surface, a substrate or a surface oxide layer, oil, dust, fingerprints and other dirt. Therefore, before the resist layer is first applied to the surface of the board and the copper foil surface cleaning roughened layer reaches a certain degree.

Inner plate: started four panels, the inner (second and third layers) is a must do first. The inner sheet is made of glass fiber and epoxy resin-based composite upper and lower surfaces of the copper sheet.

2. Cut Sheet Dry Film Lamination

Coating a photoresist: we need to make the shape of the inner plate, we first affixed dry film (resist, photoresist) over the inner layer sheet. The dry film is a polyester thin film, a photoresist film and a polyethylene protective film composed of three parts. When the foil, the dry film starting with a polyethylene protective film is peeled off, and then under the conditions of heat and pressure in the dry film is pasted on copper.

3. Image Expose & Image Develop

Exposure: In the UV irradiation, photoinitiators absorb light decompose into radicals, radical photopolymerization initiator and then polymerizing the monomer to generate a crosslinking reaction, forming insoluble in dilute alkali solution after the reaction of the polymer structure. Polymerization to continue for some time, in order to ensure the stability of the process, not to tear immediately after exposure polyester film should stay more than 15 minutes to the polymerization reaction to proceed, before developing torn polyester film.

Developer: the reaction active groups solution unexposed portions of the photosensitive film with a dilute alkali-soluble matter dissolved production down, leaving the already hardened by crosslinking the photosensitive pattern portion

4. Copper Etch

In flexible printed boards or printed board manufacturing process, the chemical reaction to the copper foil portion not to be removed, so as to form a desired circuit pattern of copper beneath the photoresist is not etched retained impact.

5. Strip Resist & Post Etch Punch & AOI Inspection & Oxide

The purpose of the film is to etch the board retained after clearing the resist layer so that the following copper exposed. "Film slag" filter and recycle waste shall be disposed of properly. If you go after the film can be washed completely clean, you might consider not pickling. Finally, the board is completely dry after washing, avoid residual moisture.

6. Layup with prepreg

Before entering pressure machine, the need to use all of multilayer materials ready to pack (Lay-up) In addition to the inner handle the job has been oxidized, but still need a protective film film (Prepreg) -. Epoxy resin impregnated glass fibers. Role of laminations is a certain order to the board covered with a protective film since the stacked and placed between the floor plate.

7. Layup with copper foil & Vacuum Lamination Press

Foil - to present the inner sheet and then covered with a layer of copper foil on both sides, and then the multilayer pressurization (within a fixed period of time necessary to measure the temperature and pressure extrusion) was cooled to room temperature after completion of the remaining is a multi-layer sheet of together.

8. CNC Drill

Under the conditions of the inner precision, CNC drilling drilling depending on the mode. Drilling high precision, to ensure that the hole is in the correct position.

9. Electroless Copper

In order to make the through-hole between the layers can be turned on (the resin and glass fiber bundle of a non-conductive portion of the wall of the hole metallization), the holes must be filled in the copper. The first step is a thin layer of copper plating in the hole, this process is completely chemical reaction. Final plated copper thickness of 50 inches millionth.

10. Cut Sheet & Dry Film Lamination

Photoresist coating: We have one in the outer coating of the photoresist.

11. Mage Expose & Image Develop

Outer exposure and development

12. Copper Pattern Electro Plating

This has become a secondary copper, the main purpose is to thicken the line of copper and copper vias thick.

13. Tin Pattern Electro Plating

Its main purpose is an etching resist, protect it covers the copper conductors will not be attacked (internal protection of all copper lines and vias) in alkaline corrosion of copper.

14. Strip Resist

We already know the purpose, just use the chemical method, the surface of the copper is exposed.

15. Copper Etch

We know that the purpose of protecting the tin partially etched foil below.

16. LPI coating side 1 & Tack Dry & LPI coating side 2 & Tack Dry & Image Expose & Image Develop & Thermal Cure Solder mask

Solder mask is exposed to the pads used, it is often said that the green oil, oil is actually digging holes in the green, the green oil does not need to cover the pads and other exposed areas. Proper cleaning can get a suitable surface features.

17. Surface finish

HASL solder coating HAL (commonly known as HAL) process is first dipped on the PCB flux, then dipping in molten solder, and then from between two air knives by compressed air with a knife in the heat air to blow off excess solder on printed circuit board, at the same time eliminate excess solder metal hole, resulting in a bright, smooth, uniform solder coating.

Gold Finger, purpose-designed Edge Connector, plug the connector as board liaison foreign exports, and therefore need to cheat the process. Chose gold because of its superior conductivity and oxidation resistance. However, because the cost of gold applies only to cheat so high, local gold plated or chemically.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!