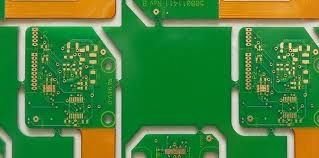

0.2 - 3.2mm 4 / 6 layer rigid flex pcb HDI Heavy copper 12 oz , FR-4 , CEM-3 base

Specifications

Basi material: FR-4,CEM-3

Layer:4/6 layer

Copper thickness: 18um

Board thickness: 0.2-3.2 mm

Specificatoin for our Flex PCB:

Basi material: FR-4,CEM-3

Layer:4 layer

Copper thickness: 18um

Board thickness: 0.2-3.2 mm

Mini Hole size: 0.2mm

Mini Space width: 0.1mm

Surface Finishing: Lead free HASL

Quality control:

1. 100% inspected before shipped.

2. Follow IPC-TM-650 perform reliability test.

3. Solderability test and thermal stress test.

4. Process control: QC and QA.

5. Apply for Certificate: UL, ISO9001, ISO14001.

Packing:

1. Inner packing: Vacuum packing / Plastic bag.

2. Outer packing: Standard carton packing.

What we can offer

1. Rigid PCB(Sigle-sided PCB, Double-sided PCB, Multy-layer PCB-up to 30 layer)

2. Flex-Rigid PCB(up to 20 layers)

3. Flexible PCB(1 to 8 layers)

4. HDI PCB

5. All kinds of high class PCBS.

PCB material we can use: FR1, FR2, HB, CEM1, CEM3, FR4, High TG/CTI FR4, Halogen Free, Rogers, Aluminium based, Leadfree compatible, Hi Frequency.

Lead Time:

Prototype (Up to 3 dm²), SS-DS-4L-6L-8L-10L : 2-5 Working days

Rigid: 10-20 Working days

Flex: 10-20 Working days

Flex-Rigid:15-25 Working days

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!