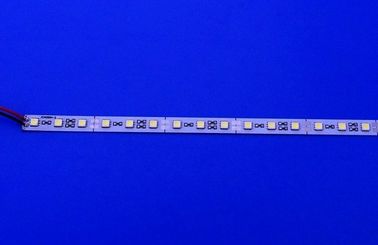

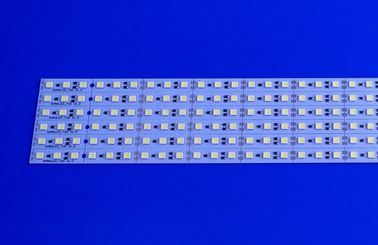

5050 / 3528 SMD LED rigid strip Aluminum PCB Board with 1oz Copper , 1.0mm Thickness

Quick Detail:

1. Model No.:SP5050R120

2. Material : Aluminum 1.0mm thickness

3. PCB size :1190*35mm for 144pcs leds , 584*35mm for 72pcs leds

4. Copper Thickness: 1oz

5. PCB Surface Finishing: HASL LEAD FREE

6. LED : 5050 SMD leds

7. Luminous Flux : 20-22lm per 5050 SMD leds

8. RIGID PCB Strip mounting SMD leds customerized

Applications:

It is used in the street light ,high way led lamp,tunnel lamp ,square lamp,road lamp, city lighting, parking spot lamp, track lighting fixtures ,scenery area ,retail lighting and other applications where high luminous flux is desired.

Description:

1.Chip: Taiwan Epistar chip

2.Silicon glue: USA Dowcorning (good glue has less lighting decreasing)

3.Powder: USA Intermatix (good powder has better performance in lumens)

4.Gold wire: Germany Herqeus 1.0mil Gold wire(for bearing bigger current, gold wire has less

5.electricity resistance than silver and cooper)

6.Led base:red/ black cooper base (for better thermal conductive/ disspate)

Applications:

General Illumination

- Outdoor & Indoor architectural lighting

- Decorative lighting

- rigid strips

- Wall washer lighting, shop light lamps

- projector light

Specifications:

|

Product Name

|

5050|3528 SMD LED rigid strips 1.2meter Custom-made

|

|

Model No

|

SP5050R120

|

|

Finishing

|

Lead-free soldering

|

|

Material

|

Taiwan Epistar chip

|

|

MOQ

|

100M

|

|

Size

|

1190*35mm for 144pcs leds , 584*35mm for 72pcs leds

|

|

Package

|

127X23X23CM for 150pcs/box

|

|

Sample

|

6-7 work days

|

|

Delivery

|

7-10 work days

|

|

Certificater

|

ROHS

|

|

Quality gurantee

|

2 years warranty

|

|

Main market

|

Europe, America, Asia

|

Shipping and delivery time:

|

DHL

|

4-5 work days

|

|

UPS

|

4-5 work days

|

|

EMS

|

7-15 work days

|

|

Fed Ex/TNT

|

3-5 work days

|

|

HK Post Air Mail Register

|

10-18 work ing days

|

|

Delivery time

|

7-10 working days

|

Competitive Advantage:

Features of 5050|3528 SMD LED rigid strips 1.2meter custom-made

* Spray painting without Lead,White oil surface and black word

* Oil Paint Features:High Temperature 280℃

* Super high Flux output and high Luminance

* Designed for large current circuit

* Low thermal resistance 12C/W

* Lead-free soldering

* SMT Reflect mounting technology

* ROHS compliant

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!