Introduction:

Focus on the most basic of PCB, components focused on one side, the other side of the wire is concentrated.Because wires only appear on one side, so this kind of PCB is called single sided PCB.

Single panel wiring diagram is given priority to with the network printing, that is, in the copper surface printed on resistance agent, to prevent welding resistance after etching printed on mark, and then punching processing way to complete the parts guide hole and the appearance.In addition, part of a small amount of diverse products, are using photosensitive resistance agent forming pattern of the photographic method.

Operating temperatures range from 130 C to 230 C. Single sided boards are available with surface finishes including Organic surface protectant (OSP), Immersion Silver, Tin, and Gold plating along with both leaded or lead-free Hot Air Solder Level (HASL).

Material:

Single sided PCB base material in paper phenolic copper paper laminated board, epoxy resin copper laminated plate is given priority to.

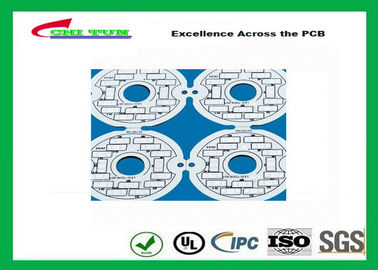

Structure:

First, the copper foil to be etched, etc. Process to obtain a circuit required, a protective film to be drilled to expose the corresponding pad. After cleaning and then rolling method to combine the two. Then the pad portion exposed gold plating or tin protection.

Production Process:

Single copper-clad plate - blanking - photochemical method/screen printing image transfer - remove corrosion was printed - cleaning, dry - hole machining - shape - dry cleaning - printing resistance welding coating - cure - printing mark symbol - cure - dry cleaning drying - pre coated flux - a finished product

Application

Single sided PCB most use in the radio, heating machine, cold storage, washing machines and other electrical appliances product, as well as the printer, vending machines, LED lighting, electronic components, such as commercial machine circuit

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!