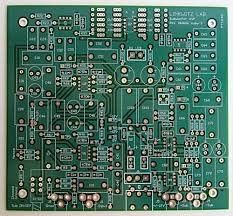

High density FR4 Printed Rigid PCB Board 2 Layer HASL Finishing & Assembly

Specifications

1.PCB Board,Printed Rigid PCB Fab&Assembly

2.UL,SGS,ROHS Certificated

3.Competitive Price,High Quality

4.Fast Delivery

WonDa, your single point of contact for pcb fabricate, components purchase and one-stop pcb assembly,also offers:

- Contract Manufacturing

- Engineering Services

- PCB Design & Assembly

- Product Design

- Prototyping

- Cable and Wire Assemblies

- Plastics and Molds

1.Printed Circuit Board process capability:

· Layers: Single Sided,2 to 30 Layer

· Board material type: FR4,CEM-1,CEM-3,ceramic substrate board, aluminum based board, high-Tg, Rogers and more

· Compound material lamination: 4 to 6 layers

· Maximum dimension: 610 x 1,100mm

· Dimension tolerance: ±0.13mm

· Board thickness coverage: 0.2 to 6.00mm

· Board thickness tolerance: ±8%

· Board thickness tolerance: ±10%

· DK thickness: 0.076 to 6.00mm

· Minimum line width: 0.10mm

· Minimum line space: 0.10mm

· Outer layer copper thickness: 8.75 to 175µm

· Inner layer copper thickness: 17.5 to 175µm

· Drilling hole diameter (mechanical drill): 0.25 to 6.00mm

· Finished hole diameter (mechanical drill): 0.20 to 6.00mm

· Hole diameter tolerance (mechanical drill): 0.05mm

· Hole position tolerance (mechanical drill): 0.075mm

· Laser drill hole size: 0.10mm

· Board thickness and hole diameter ratio: 10:1

· Solder mask type: green, yellow, black, purple, blue, white and red

· Minimum solder mask: Ø0.10mm

· Minimum size of solder mask separation ring: 0.05mm

· Solder mask oil plug hole diameter: 0.25 to 0.60mm

· Impedance control tolerance: ±10%

· Surface finish: hot air level, ENIG, immersion silver, gold plating, immersion tin and gold finger

♦ All of the above description is to demonstrate the ability of our factory, if you have specific requirements, please contact us.

2.Lead time

Samples:4 to 5 days

Mass produce:7 to 15 days depend on your PCB orders

3.Payment Terms

T/T, WEST UNION, Paypal Accepted

4.produce capacity

250000 Squre meter per year

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!